Adding Servo-Controlled Turnouts to Your Model Railway with DCC-EX and EXRAIL

Introduction

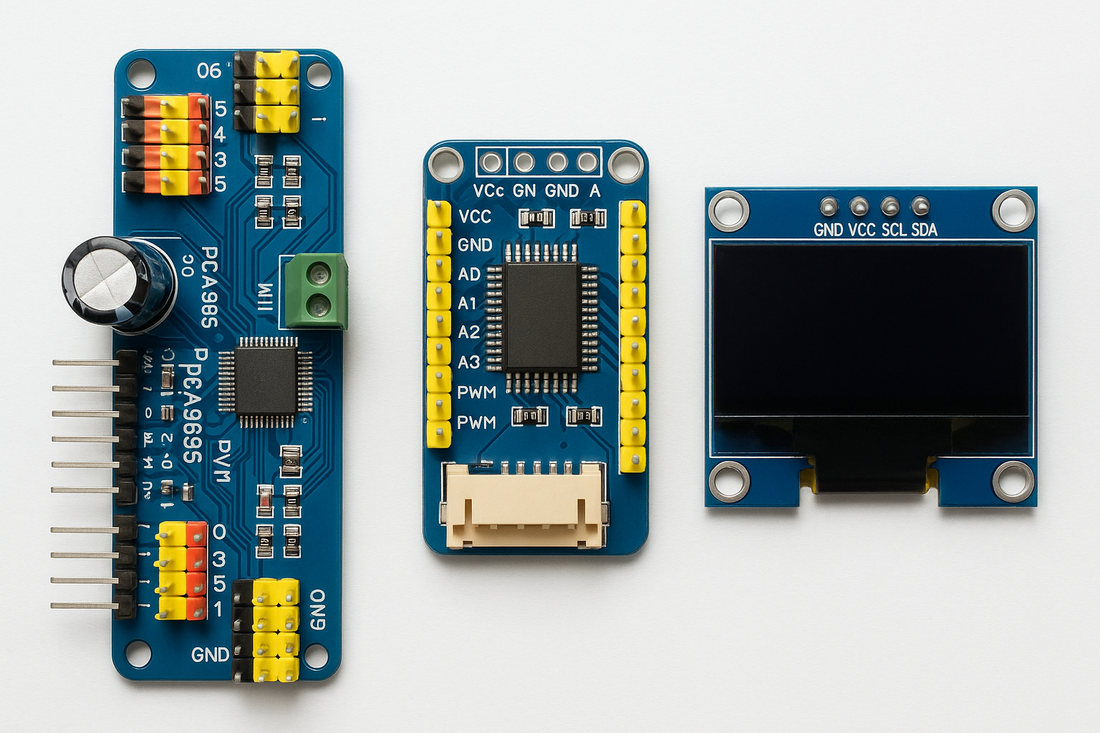

You can add reliable, low-cost servo turnout control to a running DCC-EX system using a PCA9685 (I²C) 16-channel servo driver and EXRAIL. This guide covers wiring, HAL setup, turnout definition, and calibration.

Hardware You Need

- PCA9685 16-channel I²C servo board

- Servos (one per turnout)

- Regulated 5 V power supply for servos (separate from CommandStation)

- I²C connection to your CommandStation (Qwiic on CSB1/EX8874 or SDA/SCL pins)

- Cables and common ground (CS GND ↔ PCA9685 GND ↔ 5 V PSU GND)

⚠️ Power warning: Do not power servos from the CommandStation. Use a separate 5 V supply to the PCA9685’s servo power input and share ground with the CommandStation.

Wiring & Bring-Up

- Connect PCA9685 SDA→SDA, SCL→SCL, VCC (logic 3.3/5 V) and GND to the CommandStation.

- Feed the servos from the separate 5 V supply connected to the PCA9685’s servo power rail; share GND with the CommandStation.

- Power up and watch the serial log; it will list detected I²C devices and the PCA9685’s I²C address (commonly

0x40, but verify).

Note: If you see

check the SDA/SCL wiring and ensure correct orientation.< No I2C Devices found >

HAL Configuration (PCA9685)

Declare the PCA9685 in myAutomation.h using the HAL(...) macro.

// start vPin, count, I2C address

HAL(PCA9685, 100, 16, 0x40)

vPin → Channel Map

- vPin 100 → PCA9685 ch 0

- vPin 101 → ch 1

- …

- vPin 115 → ch 15

Adding another PCA9685? Give it a new address (e.g., 0x41) and a new vPin block:

HAL(PCA9685, 116, 16, 0x41) // vPins 116–131

Defining Servo Turnouts in myAutomation.h

After registering the PCA9685, define each servo turnout using SERVO_TURNOUT.

Syntax

SERVO_TURNOUT(id, vPin, active_angle, inactive_angle, profile, description)

Parameters

- id → Turnout ID number (referenced in throttles/automation)

- vPin → Virtual pin assigned to servo (from PCA9685 block)

- active_angle → Servo position for "thrown"

- inactive_angle → Servo position for "closed"

- profile → Motion profile (e.g., "Fast", "Slow")

- description → Label for turnout

Example

// First servo (channel 0, vPin 100)

SERVO_TURNOUT(1, 100, 250, 250, "Fast", "Turnout 1")

// Second servo (channel 1, vPin 101)

SERVO_TURNOUT(2, 101, 250, 250, "Fast", "Turnout 2")

Both active and inactive angles are initially set to the same value (250) so the servo has a safe starting point. You can later fine-tune these.

Important: After adding or editing HAL(...) or SERVO_TURNOUT() entries, you must recompile and upload the sketch to the CommandStation. This ensures the PCA9685 is properly detected and initialised at startup.

Calibrating Servo Angles

- Start with both angles equal (e.g., 250, 250).

- Use the EX-Toolbox Android application to make incremental adjustments to the servo position. This allows you to carefully move the servo until the turnout aligns correctly without stressing the mechanism.

- Once you have found the correct active and inactive angles with EX-Toolbox, update your

SERVO_TURNOUT()command inmyAutomation.hwith these values. - After updating the

SERVO_TURNOUT()command with your new angles, you must recompile and upload the sketch again to the CommandStation before testing. - Test turnout via throttle or EXRAIL commands:

- Closed →

<T 1 C> - Thrown →

<T 1 T>

- Closed →

- Repeat for each turnout until all are calibrated.

Note: Many throttles and consoles require angle brackets < > around the turnout commands. Do not omit them.

Example After Tuning

SERVO_TURNOUT(1, 100, 120, 400, "Fast", "Turnout 1")

Example Block: Four Servos (vPins 100–103)

// PCA9685 mapped at vPins 100–115

HAL(PCA9685, 100, 16, 0x40)

// Define four turnouts

SERVO_TURNOUT(1, 100, 250, 250, "Fast", "Turnout 1")

SERVO_TURNOUT(2, 101, 250, 250, "Fast", "Turnout 2")

SERVO_TURNOUT(3, 102, 250, 250, "Fast", "Turnout 3")

SERVO_TURNOUT(4, 103, 250, 250, "Fast", "Turnout 4")

Using EngineDriver or Other Throttle Apps

When using EngineDriver (an Android application) to control turnouts:

- See EngineDriver First Connection to DCC for how to connect EngineDriver to your DCC-EX system.

- Once connected, EngineDriver will briefly display "Points Loaded".

- Click the three dots in the top-right corner and select Turnouts/Points.

- You will see the turnouts you have configured.

- Tap Throw to throw the turnout or Close to close it.

It really is that simple — once set up, your turnouts can be operated directly from the Android throttle app.

Troubleshooting

| Problem | Cause | Solution |

|---|---|---|

| PCA9685 not detected | Wrong wiring/I²C addr | Check SDA/SCL wiring, verify address in log |

| Servo not moving | Power issue | Confirm 5 V supply + common ground |

| Chatter/jitter | Over-travel / weak PSU | Adjust angles, use stable 5 V supply |

| Wrong channel moves | Wrong vPin mapping | Recheck vPin ↔ channel mapping |

✅ With HAL configured, turnouts defined, and servos calibrated (using EX-Toolbox for precise adjustments), your DCC-EX system now supports servo-controlled turnouts through EXRAIL!